An article will help you understand what a capacitor housing is

Understanding Capacitor Housing

I. Introduction

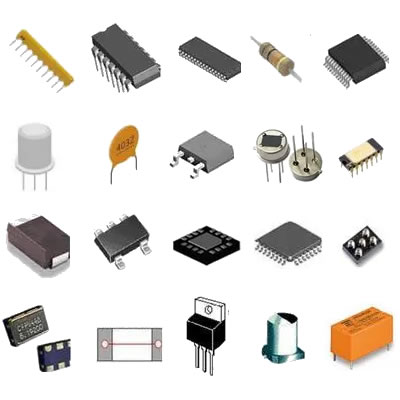

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They store electrical energy temporarily and release it when needed, making them essential for various applications, from consumer electronics to industrial machinery. However, the effectiveness and reliability of capacitors are significantly influenced by their housing. In this article, we will explore what capacitor housing is, its types, materials, design considerations, manufacturing processes, applications, and the challenges and innovations in this field.

II. What is Capacitor Housing?

A. Definition and Purpose

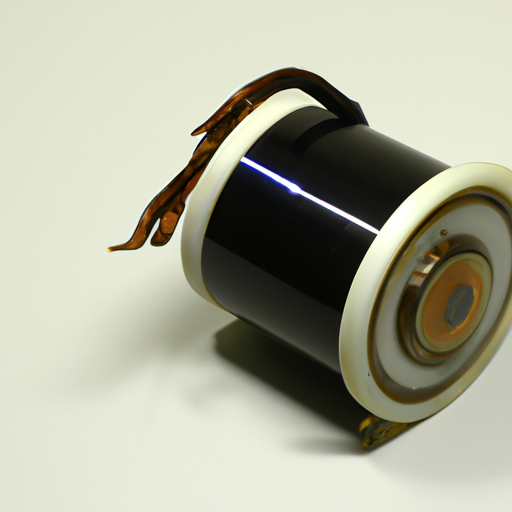

Capacitor housing refers to the protective casing that encases a capacitor. Its primary purpose is to safeguard the internal components of the capacitor from environmental factors, mechanical stress, and electrical interference. The housing also plays a vital role in ensuring the capacitor operates efficiently and safely within an electronic circuit.

B. Types of Capacitor Housings

Capacitor housings come in various types, each designed to meet specific requirements based on the application and environment.

1. **Plastic Housings**: These are lightweight and cost-effective, commonly used in consumer electronics. They provide adequate insulation and protection against moisture and dust.

2. **Metal Housings**: Metal housings offer superior durability and heat dissipation. They are often used in high-performance applications, such as automotive and industrial machinery, where robustness is essential.

3. **Ceramic Housings**: Ceramic housings are known for their excellent electrical insulation properties and thermal stability. They are typically used in high-frequency applications and environments with extreme temperatures.

C. Key Functions of Capacitor Housing

The housing of a capacitor serves several critical functions:

1. **Protection**: It shields the capacitor from physical damage, moisture, and contaminants that could affect its performance.

2. **Insulation**: The housing provides electrical insulation, preventing short circuits and ensuring safe operation.

3. **Heat Dissipation**: Capacitors can generate heat during operation, and the housing helps dissipate this heat, maintaining optimal performance and longevity.

III. Materials Used in Capacitor Housing

A. Common Materials

The choice of material for capacitor housing is crucial for its performance and reliability. Common materials include:

1. **Polypropylene**: Known for its excellent electrical insulation and thermal resistance, polypropylene is widely used in plastic housings.

2. **Polyester**: This material offers good mechanical strength and is often used in capacitors that require durability.

3. **Aluminum**: Metal housings made of aluminum provide excellent heat dissipation and are commonly used in high-performance applications.

4. **Ceramic**: Ceramic materials are used for their superior electrical insulation and thermal stability, making them ideal for high-frequency applications.

B. Properties of These Materials

The materials used in capacitor housing possess specific properties that make them suitable for their intended applications:

1. **Electrical Insulation**: Effective insulation is essential to prevent electrical leakage and ensure safe operation.

2. **Thermal Resistance**: Materials must withstand heat generated during operation without degrading.

3. **Mechanical Strength**: The housing must be robust enough to protect the capacitor from physical stress and environmental factors.

C. Selection Criteria for Housing Materials

When selecting materials for capacitor housing, several criteria must be considered, including:

Electrical properties: The material should provide adequate insulation and withstand the voltage levels of the application.

Thermal properties: The ability to dissipate heat effectively is crucial for maintaining performance.

Mechanical properties: The housing must be durable and resistant to physical damage.

Cost-effectiveness: The material should be affordable while meeting performance requirements.

IV. Design Considerations for Capacitor Housing

A. Size and Shape

The size and shape of capacitor housing can significantly impact circuit design. Designers must consider:

1. **Impact on Circuit Design**: The housing must fit within the overall design of the electronic device, ensuring compatibility with other components.

2. **Space Constraints in Electronic Devices**: As devices become more compact, capacitor housings must be designed to maximize space efficiency without compromising performance.

B. Environmental Factors

Capacitor housings must be designed to withstand various environmental conditions:

1. **Temperature Range**: The housing should be able to operate effectively within the specified temperature range of the application.

2. **Humidity and Moisture Resistance**: In humid environments, the housing must prevent moisture ingress that could lead to failure.

3. **Chemical Exposure**: The material should resist degradation from exposure to chemicals or solvents present in the operating environment.

C. Electrical Characteristics

The electrical characteristics of the capacitor must also influence housing design:

1. **Voltage Rating**: The housing must be able to withstand the maximum voltage the capacitor will encounter.

2. **Capacitance Value**: The design should accommodate the specific capacitance value required for the application.

3. **Frequency Response**: For high-frequency applications, the housing must minimize parasitic effects that could impact performance.

V. Manufacturing Processes of Capacitor Housing

A. Overview of Manufacturing Techniques

The manufacturing process for capacitor housing involves several techniques, including:

1. **Injection Molding**: This process is commonly used for plastic housings, allowing for precise shapes and designs.

2. **Extrusion**: Used for creating long, continuous shapes, extrusion is often employed for specific types of plastic housings.

3. **Stamping**: Metal housings are often produced through stamping, which allows for high-volume production with consistent quality.

B. Quality Control Measures

Ensuring the quality of capacitor housings is critical for reliability. Quality control measures include:

1. **Testing for Durability**: Housings are subjected to mechanical stress tests to ensure they can withstand physical impacts.

2. **Electrical Testing**: Capacitor housings undergo electrical testing to verify insulation properties and voltage ratings.

3. **Compliance with Industry Standards**: Manufacturers must adhere to industry standards to ensure safety and performance.

VI. Applications of Capacitor Housing

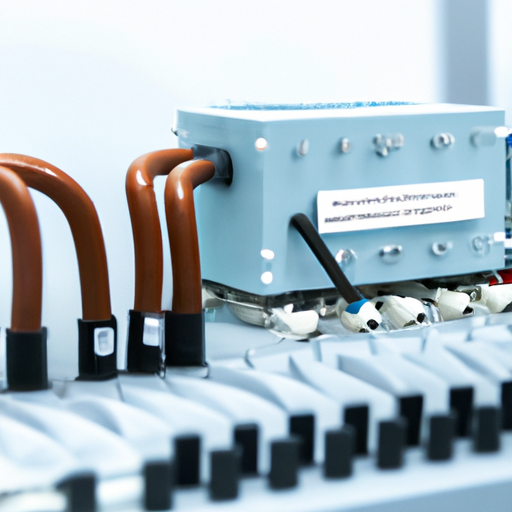

Capacitor housings are utilized in a wide range of applications, including:

A. Consumer Electronics

In devices such as smartphones, laptops, and televisions, capacitor housings protect components and ensure reliable performance.

B. Automotive Industry

Capacitors in vehicles require robust housings to withstand harsh conditions, including temperature fluctuations and vibrations.

C. Industrial Machinery

In industrial settings, capacitors are used for power factor correction and motor control, necessitating durable housings.

D. Renewable Energy Systems

Capacitors play a vital role in solar inverters and wind turbines, where reliable housing is essential for performance.

E. Telecommunications

In telecommunications equipment, capacitors are used for signal processing, requiring housings that minimize interference.

VII. Challenges and Innovations in Capacitor Housing

A. Common Challenges Faced in Capacitor Housing Design

1. **Miniaturization**: As electronic devices become smaller, designing compact capacitor housings that maintain performance is a significant challenge.

2. **Cost-effectiveness**: Balancing performance with cost is crucial for manufacturers, especially in competitive markets.

3. **Sustainability**: There is a growing demand for environmentally friendly materials and processes in capacitor housing production.

B. Recent Innovations and Trends

1. **Biodegradable Materials**: Researchers are exploring biodegradable materials for capacitor housings to reduce environmental impact.

2. **Advanced Thermal Management Solutions**: Innovations in thermal management are helping to improve heat dissipation in capacitor housings.

3. **Smart Capacitors with Integrated Sensors**: The development of smart capacitors that can monitor their performance and health is an exciting trend in the industry.

VIII. Conclusion

Capacitor housing is a critical aspect of capacitor design and functionality. It provides protection, insulation, and heat dissipation, ensuring that capacitors operate effectively in various applications. As technology advances, the demand for innovative and sustainable capacitor housing solutions will continue to grow. Understanding the intricacies of capacitor housing can lead to better design choices and improved performance in electronic devices. We encourage readers to explore further and deepen their understanding of capacitors and their essential role in modern electronics.

IX. References

For those interested in delving deeper into the topic of capacitor housing, consider exploring the following resources:

1. Academic papers on capacitor technology and materials.

2. Industry standards and guidelines for capacitor manufacturing.

3. Articles on recent innovations in capacitor design and applications.

By understanding the significance of capacitor housing, we can appreciate the vital role it plays in the reliability and efficiency of electronic circuits.