What is the purchase price of the latest capacitor parameters?

What is the Purchase Price of the Latest Capacitor Parameters?

I. Introduction

Capacitors are fundamental components in electronic devices, serving as energy storage units that play a crucial role in various applications, from power supply circuits to signal processing. They store electrical energy temporarily and release it when needed, making them essential for maintaining voltage levels, filtering signals, and stabilizing power supplies. As technology advances, the demand for capacitors with specific parameters has increased, leading to a diverse market with varying purchase prices. This article aims to explore the purchase price of capacitors based on their parameters, helping consumers and manufacturers make informed decisions.

II. Understanding Capacitor Parameters

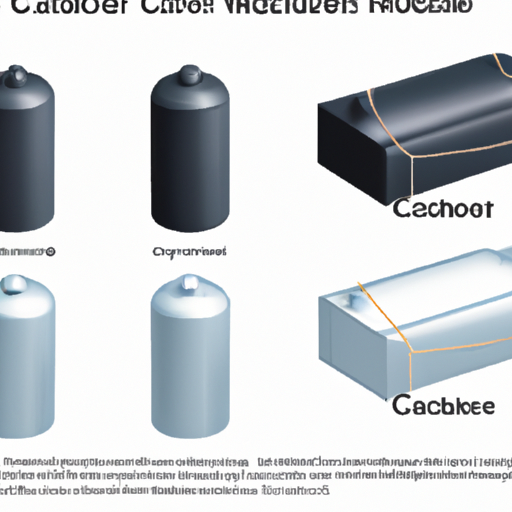

A. Types of Capacitors

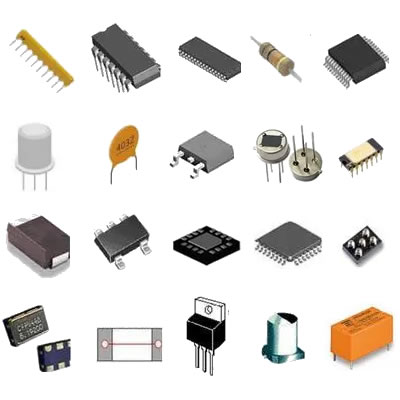

Capacitors come in various types, each designed for specific applications and performance characteristics:

1. **Ceramic Capacitors**: Known for their small size and high capacitance values, ceramic capacitors are widely used in high-frequency applications. They are generally cost-effective and have low ESR, making them suitable for decoupling and filtering.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values in a compact form factor, making them ideal for power supply applications. However, they have a polarized design and can be sensitive to voltage and temperature variations.

3. **Film Capacitors**: Film capacitors are known for their stability and reliability. They are often used in audio applications and power electronics due to their low ESR and high voltage ratings.

4. **Tantalum Capacitors**: Tantalum capacitors provide high capacitance in a small package and are known for their reliability. They are often used in military and aerospace applications, where performance and reliability are critical.

B. Key Parameters Affecting Capacitor Performance

Several key parameters influence the performance and suitability of capacitors for specific applications:

1. **Capacitance Value (Farads)**: This parameter indicates the amount of charge a capacitor can store. Higher capacitance values are typically associated with larger physical sizes and higher costs.

2. **Voltage Rating (Volts)**: The voltage rating indicates the maximum voltage a capacitor can handle without failing. Capacitors with higher voltage ratings are generally more expensive due to the materials and manufacturing processes involved.

3. **Equivalent Series Resistance (ESR)**: ESR is a measure of the internal resistance of a capacitor, affecting its efficiency and performance in high-frequency applications. Lower ESR values are preferred, especially in power supply circuits.

4. **Temperature Coefficient**: This parameter indicates how a capacitor's capacitance changes with temperature. Capacitors with stable temperature coefficients are essential for applications requiring precise performance.

5. **Lifetime and Reliability**: The expected lifespan of a capacitor is crucial, especially in critical applications. Capacitors with longer lifetimes often come at a premium price.

C. The Relationship Between Parameters and Application

Understanding the relationship between capacitor parameters and their intended applications is vital for selecting the right component. For instance, a high-frequency circuit may require low ESR ceramic capacitors, while a power supply might benefit from high-capacitance electrolytic capacitors. The choice of capacitor directly impacts the performance, reliability, and overall cost of the electronic device.

III. Factors Influencing Purchase Price

A. Material Composition

The materials used in capacitor construction significantly impact their cost. For example, tantalum capacitors, which use rare materials, tend to be more expensive than ceramic capacitors. The choice of dielectric material, such as polyester or polypropylene in film capacitors, also affects pricing.

B. Manufacturing Processes

The complexity of manufacturing processes plays a crucial role in determining the price of capacitors. Advanced technologies, such as thin-film deposition and automated assembly, can increase production costs. Additionally, the scale of production can lead to economies of scale, reducing the per-unit cost for manufacturers.

C. Market Demand and Supply Dynamics

Market demand and supply dynamics are critical factors influencing capacitor pricing. The electronics industry is subject to rapid changes in demand, driven by trends such as the rise of electric vehicles, renewable energy systems, and consumer electronics. Seasonal fluctuations, such as increased demand during holiday seasons, can also impact prices.

D. Brand Reputation and Quality Assurance

Established brands often command higher prices due to their reputation for quality and reliability. Consumers may be willing to pay a premium for capacitors from trusted manufacturers that adhere to strict certification and testing standards. This brand influence can significantly affect the overall pricing landscape.

IV. Price Ranges for Different Capacitor Types

A. Overview of Current Market Prices

The market prices for capacitors can vary widely based on type and specifications:

1. **Low-End Capacitors**: Basic ceramic capacitors can be found for as little as $0.01 to $0.10 per unit, making them accessible for high-volume applications.

2. **Mid-Range Capacitors**: Electrolytic capacitors typically range from $0.10 to $1.00, depending on capacitance and voltage ratings.

3. **High-End Capacitors**: Specialized film and tantalum capacitors can range from $1.00 to $10.00 or more, reflecting their advanced performance characteristics and reliability.

B. Case Studies of Specific Capacitor Models

1. **Example of a Popular Ceramic Capacitor**: The Murata GRM series ceramic capacitors are widely used in consumer electronics, with prices ranging from $0.05 to $0.50 based on capacitance and voltage ratings.

2. **Example of a High-Performance Electrolytic Capacitor**: The Nichicon UHE series electrolytic capacitors, known for their reliability, typically cost between $0.50 and $2.00, depending on specifications.

3. **Example of a Specialized Film Capacitor**: The WIMA MKS series film capacitors, used in audio applications, can range from $1.00 to $5.00, reflecting their high-quality construction and performance.

C. Price Comparison Across Different Suppliers

When purchasing capacitors, it's essential to compare prices across different suppliers. Online marketplaces, electronic component distributors, and manufacturer websites often provide varying prices for the same components. Bulk purchasing can also lead to significant discounts, making it worthwhile for manufacturers and hobbyists alike.

V. Future Trends in Capacitor Pricing

A. Technological Advancements

As technology continues to evolve, innovations in capacitor design and materials are expected to impact pricing structures. New manufacturing techniques may reduce costs while improving performance, leading to more competitive pricing in the market.

B. Environmental Considerations

The shift towards sustainable materials and environmentally friendly manufacturing processes is gaining traction. While this may initially increase costs, it could lead to long-term savings and a more stable pricing environment as demand for eco-friendly products rises.

C. Predictions for Market Trends

Looking ahead, several trends are likely to influence capacitor pricing:

1. **Expected Changes in Demand**: The growing demand for electric vehicles and renewable energy systems is expected to drive up the need for high-performance capacitors, potentially leading to price increases.

2. **Potential Impacts of Global Events**: Supply chain disruptions, such as those experienced during the COVID-19 pandemic, can lead to price volatility. Manufacturers must remain agile to adapt to these changes.

VI. Conclusion

In summary, understanding the purchase price of capacitors based on their parameters is essential for making informed decisions in the electronics market. Factors such as material composition, manufacturing processes, market dynamics, and brand reputation all play a role in determining pricing. As technology advances and environmental considerations become more prominent, the landscape of capacitor pricing is likely to evolve. By staying informed about these trends, consumers and manufacturers can navigate the complexities of the capacitor market effectively.

VII. References

1. Murata Manufacturing Co., Ltd. (2023). GRM Series Ceramic Capacitors. Retrieved from [Murata](https://www.murata.com)

2. Nichicon Corporation. (2023). UHE Series Electrolytic Capacitors. Retrieved from [Nichicon](https://www.nichicon.co.jp)

3. WIMA GmbH & Co. KG. (2023). MKS Series Film Capacitors. Retrieved from [WIMA](https://www.wima.de)

4. Electronics Weekly. (2023). Trends in Capacitor Pricing. Retrieved from [Electronics Weekly](https://www.electronicsweekly.com)

5. IEEE Xplore. (2023). Advances in Capacitor Technology. Retrieved from [IEEE](https://ieeexplore.ieee.org)

This blog post provides a comprehensive overview of the factors influencing capacitor pricing, helping readers understand the complexities of the market and make informed purchasing decisions.