What kind of product is a motor capacitor?

What Kind of Product is a Motor Capacitor?

I. Introduction

In the realm of electrical systems, motor capacitors play a crucial role in ensuring the efficient operation of various devices. A motor capacitor is a specialized component designed to store and release electrical energy, thereby enhancing the performance of electric motors. This article aims to provide a comprehensive understanding of motor capacitors, their types, applications, and maintenance, ultimately highlighting their significance in both household and industrial settings.

II. Understanding Capacitors

A. Basic Principles of Capacitors

1. **Definition and Function**: A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, an electric charge accumulates on the plates, allowing the capacitor to store energy.

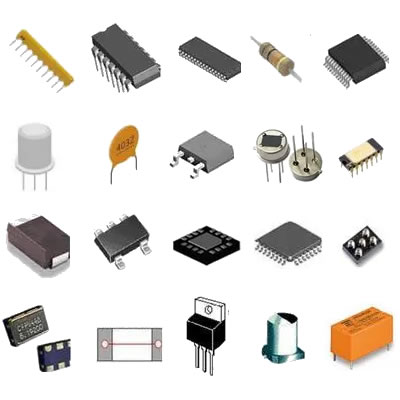

2. **Types of Capacitors**: Capacitors come in various types, including ceramic, electrolytic, tantalum, and film capacitors. Each type has unique characteristics and applications, but they all serve the fundamental purpose of energy storage and management in electrical circuits.

B. Role of Capacitors in Electrical Circuits

1. **Energy Storage**: Capacitors can store energy for later use, making them essential in applications where a quick release of energy is required.

2. **Voltage Regulation**: Capacitors help stabilize voltage levels in circuits, ensuring that devices receive a consistent power supply.

3. **Power Factor Correction**: In AC circuits, capacitors can improve the power factor, which is the ratio of real power to apparent power. This correction leads to more efficient energy use and reduced energy costs.

III. What is a Motor Capacitor?

A. Specific Function of Motor Capacitors

Motor capacitors are specifically designed to enhance the performance of electric motors. They come in two primary types: starting capacitors and run capacitors.

1. **Starting Capacitors**: These capacitors provide an initial boost of energy to start the motor. They are typically used in single-phase motors, where they help overcome inertia and get the motor running.

2. **Run Capacitors**: Once the motor is running, run capacitors maintain the motor's efficiency by providing a continuous supply of energy. They help improve the motor's power factor and overall performance.

B. How Motor Capacitors Work

1. **Electrical Characteristics**: Motor capacitors are rated by their capacitance value (measured in microfarads, or µF) and voltage rating. These specifications determine their ability to store and release energy effectively.

2. **Interaction with Motor Windings**: Motor capacitors work in conjunction with the motor windings to create a phase shift in the electrical current. This phase shift is essential for generating the magnetic field required for motor operation.

IV. Types of Motor Capacitors

A. Starting Capacitors

1. **Purpose and Application**: Starting capacitors are used to provide the necessary torque to start the motor. They are typically found in applications such as air conditioning units, refrigerators, and small pumps.

2. **Characteristics and Specifications**: Starting capacitors usually have a higher capacitance value than run capacitors and are designed to operate for a short duration before being disconnected from the circuit.

B. Run Capacitors

1. **Purpose and Application**: Run capacitors are used to improve the efficiency of the motor during operation. They are commonly found in HVAC systems, fans, and other continuous-duty applications.

2. **Characteristics and Specifications**: Run capacitors have a lower capacitance value than starting capacitors and are designed for continuous operation. They are typically rated for longer life and stability.

C. Dual-Run Capacitors

1. **Definition and Use Cases**: Dual-run capacitors combine the functions of both starting and run capacitors into a single unit. They are often used in applications where space is limited, such as in compact HVAC systems.

2. **Advantages and Disadvantages**: The primary advantage of dual-run capacitors is their space-saving design. However, they may not provide the same level of performance as separate capacitors in some applications.

V. Applications of Motor Capacitors

A. Common Uses in Household Appliances

1. **Air Conditioners**: Motor capacitors are essential for the efficient operation of air conditioning units, providing the necessary starting torque and maintaining performance during operation.

2. **Refrigerators**: In refrigerators, motor capacitors help the compressor start and run efficiently, ensuring proper cooling.

3. **Washing Machines**: Motor capacitors in washing machines enable the motor to start and run smoothly, contributing to effective washing cycles.

B. Industrial Applications

1. **Pumps**: In industrial settings, motor capacitors are used in pumps to ensure reliable starting and operation, particularly in applications involving water and other fluids.

2. **Fans**: Motor capacitors are critical in fan applications, providing the necessary energy to start and maintain airflow.

3. **Conveyors**: In conveyor systems, motor capacitors help ensure that motors start quickly and run efficiently, contributing to overall productivity.

C. Importance in HVAC Systems

Motor capacitors are vital components in HVAC systems, where they help maintain the efficiency and reliability of heating and cooling equipment. Proper functioning of motor capacitors ensures that HVAC systems operate smoothly, providing comfort and energy efficiency.

VI. Selecting the Right Motor Capacitor

A. Key Factors to Consider

1. **Voltage Rating**: It is crucial to select a motor capacitor with a voltage rating that matches or exceeds the motor's operating voltage to prevent failure.

2. **Capacitance Value**: The capacitance value must be appropriate for the specific motor application. Using a capacitor with the wrong capacitance can lead to poor performance or damage.

3. **Type of Motor**: Different motors require different types of capacitors. Understanding the motor's specifications is essential for selecting the right capacitor.

B. Importance of Matching Specifications

Using a motor capacitor that matches the motor's specifications is vital for optimal performance. Mismatched capacitors can lead to overheating, reduced efficiency, and potential motor failure.

C. Consequences of Using Incorrect Capacitors

Using the wrong motor capacitor can result in various issues, including poor motor performance, increased energy consumption, and even permanent damage to the motor. It is essential to ensure that the selected capacitor meets the necessary specifications.

VII. Maintenance and Troubleshooting

A. Signs of a Failing Motor Capacitor

1. **Symptoms in Motor Performance**: A failing motor capacitor may cause the motor to struggle to start, run inefficiently, or produce unusual noises.

2. **Visual Inspection Tips**: Inspecting the capacitor for physical signs of damage, such as bulging, leaking, or discoloration, can help identify potential issues.

B. Testing Motor Capacitors

1. **Tools Required**: To test a motor capacitor, you will need a multimeter capable of measuring capacitance.

2. **Step-by-Step Testing Process**: Disconnect the capacitor from the circuit, discharge it safely, and then use the multimeter to measure its capacitance. Compare the reading to the capacitor's rated value to determine if it is functioning correctly.

C. Replacement and Disposal Considerations

When replacing a motor capacitor, it is essential to select a compatible unit and follow proper disposal guidelines for electronic components to minimize environmental impact.

VIII. Conclusion

Motor capacitors are integral components in various electrical systems, playing a vital role in the performance and efficiency of electric motors. Understanding their types, applications, and maintenance is essential for anyone working with electrical devices. As technology advances, motor capacitors are likely to evolve, leading to improved performance and energy efficiency. In conclusion, motor capacitors are indispensable in modern electrical systems, ensuring that devices operate smoothly and efficiently.

IX. References

For further reading and resources on motor capacitors, consider exploring industry standards and guidelines, as well as technical manuals from capacitor manufacturers. Understanding these resources can provide deeper insights into the specifications and applications of motor capacitors.