What are the types of popular capacitor grounding products?

What are the Types of Popular Capacitor Grounding Products?

I. Introduction

In the realm of electrical systems, the concept of grounding is paramount. Grounding serves as a safety mechanism, ensuring that electrical faults do not lead to hazardous situations. One critical aspect of grounding involves capacitors, which play a vital role in managing electrical energy. This article delves into the types of popular capacitor grounding products, their functions, and their significance in maintaining safe and efficient electrical systems.

II. Understanding Capacitors and Their Role in Electrical Systems

A. Basic Function of Capacitors

Capacitors are passive electrical components that store and release electrical energy. They are essential in various applications, including filtering, energy storage, and power factor correction. By temporarily holding charge, capacitors help stabilize voltage and improve the efficiency of electrical systems.

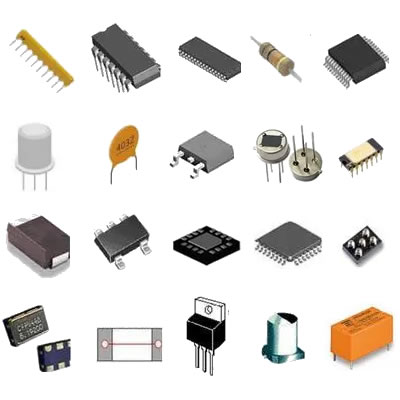

B. Types of Capacitors

1. **Electrolytic Capacitors**: These capacitors are polarized and typically used in applications requiring high capacitance values, such as power supply circuits.

2. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are widely used in high-frequency applications and are non-polarized.

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric and are favored for their low loss and high insulation resistance.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance in a small package, making them ideal for compact electronic devices.

C. The Need for Grounding Capacitors

Grounding capacitors is essential to prevent electrical shock, equipment damage, and system failures. Proper grounding ensures that any excess charge is safely dissipated, protecting both personnel and equipment.

III. The Concept of Grounding in Electrical Systems

A. Definition of Grounding

Grounding refers to the process of connecting electrical systems to the earth or a conductive body that serves as a reference point. This connection provides a safe path for electrical currents to flow in case of faults.

B. Types of Grounding

1. **System Grounding**: This involves connecting the neutral point of a power system to the ground, ensuring that the system remains stable during faults.

2. **Equipment Grounding**: This type of grounding protects equipment by connecting its metal parts to the ground, preventing electric shock.

3. **Functional Grounding**: This is used for specific functions, such as signal reference in communication systems.

C. Benefits of Proper Grounding

Proper grounding enhances safety, reduces the risk of electrical fires, and improves the reliability of electrical systems. It also helps in minimizing electromagnetic interference, ensuring that sensitive equipment operates effectively.

IV. Types of Popular Capacitor Grounding Products

A. Grounding Resistors

1. Purpose and Function

Grounding resistors are used to limit the fault current in a grounded system. They provide a controlled path for fault currents, reducing the risk of equipment damage and ensuring safety.

2. Types of Grounding Resistors

Neutral Grounding Resistors (NGR): These resistors are connected to the neutral point of a transformer or generator, limiting the fault current during a ground fault.

Grounding Transformer Resistors: These are used in conjunction with grounding transformers to provide a low-resistance path for fault currents.

B. Grounding Bars and Strips

1. Description and Use

Grounding bars and strips are conductive materials used to connect multiple grounding conductors. They provide a common grounding point for various electrical components, ensuring effective grounding.

2. Materials Used

Typically made from copper or aluminum, grounding bars and strips are designed to withstand corrosion and provide excellent conductivity.

C. Grounding Kits

1. Components of Grounding Kits

Grounding kits usually include grounding conductors, clamps, connectors, and other necessary components for establishing a reliable grounding system.

2. Applications and Benefits

These kits are versatile and can be used in various applications, including industrial, commercial, and residential settings. They simplify the grounding process and ensure compliance with safety standards.

D. Grounding Rods and Plates

1. Types of Grounding Rods

Grounding rods are typically made of copper or galvanized steel and are driven into the ground to establish a low-resistance path to earth. Common types include:

Copper Grounding Rods: Known for their excellent conductivity and resistance to corrosion.

Galvanized Steel Grounding Rods: More economical but may require additional maintenance due to corrosion.

2. Installation and Maintenance

Proper installation involves driving the rod into the ground to a depth that ensures effective grounding. Regular maintenance checks are essential to ensure that the grounding system remains functional.

E. Surge Protection Devices (SPDs)

1. Role of SPDs in Grounding

Surge protection devices protect electrical systems from voltage spikes caused by lightning strikes or switching operations. They divert excess voltage to the ground, preventing damage to sensitive equipment.

2. Types of SPDs

Type 1 SPDs: Installed at the service entrance, protecting the entire electrical system.

Type 2 SPDs: Installed at the distribution panel, providing additional protection for branch circuits.

F. Capacitor Banks with Integrated Grounding

1. Overview of Capacitor Banks

Capacitor banks are assemblies of multiple capacitors used to improve power factor and stabilize voltage in electrical systems.

2. Importance of Integrated Grounding Solutions

Many modern capacitor banks come with integrated grounding solutions, ensuring that the entire system is grounded effectively. This integration simplifies installation and enhances safety.

V. Factors to Consider When Choosing Capacitor Grounding Products

A. Application Requirements

Different applications may require specific grounding solutions. Understanding the unique needs of your electrical system is crucial in selecting the right products.

B. Environmental Conditions

Consider the environmental factors, such as humidity, temperature, and exposure to corrosive elements, which can affect the performance and longevity of grounding products.

C. Compliance with Standards and Regulations

Ensure that the grounding products comply with relevant industry standards and regulations to guarantee safety and reliability.

D. Cost Considerations

While cost is an important factor, it should not compromise safety and quality. Investing in reliable grounding products can prevent costly damages in the long run.

VI. Installation and Maintenance of Capacitor Grounding Products

A. Best Practices for Installation

Follow manufacturer guidelines and industry standards during installation. Properly sized conductors, secure connections, and adequate grounding depth are essential for effective grounding.

B. Regular Maintenance and Inspection

Routine inspections and maintenance are vital to ensure that grounding systems remain functional. Look for signs of corrosion, loose connections, or physical damage.

C. Troubleshooting Common Issues

Common issues may include high resistance in grounding connections or inadequate grounding. Regular testing and monitoring can help identify and resolve these problems promptly.

VII. Conclusion

In conclusion, capacitor grounding is a critical aspect of electrical systems that ensures safety and reliability. Understanding the various types of popular capacitor grounding products, such as grounding resistors, bars, kits, rods, surge protection devices, and integrated capacitor banks, is essential for effective grounding solutions. By considering application requirements, environmental conditions, compliance, and cost, you can choose the right grounding products for your needs. Proper installation and maintenance will further enhance the safety and efficiency of your electrical systems.

VIII. References

A. Suggested Reading and Resources

- National Electrical Code (NEC)

- Institute of Electrical and Electronics Engineers (IEEE) Standards

B. Industry Standards and Guidelines

- International Electrotechnical Commission (IEC) Guidelines

- Underwriters Laboratories (UL) Standards

By understanding and implementing effective capacitor grounding solutions, you can ensure the safety and efficiency of your electrical systems, protecting both equipment and personnel from potential hazards.