Part number

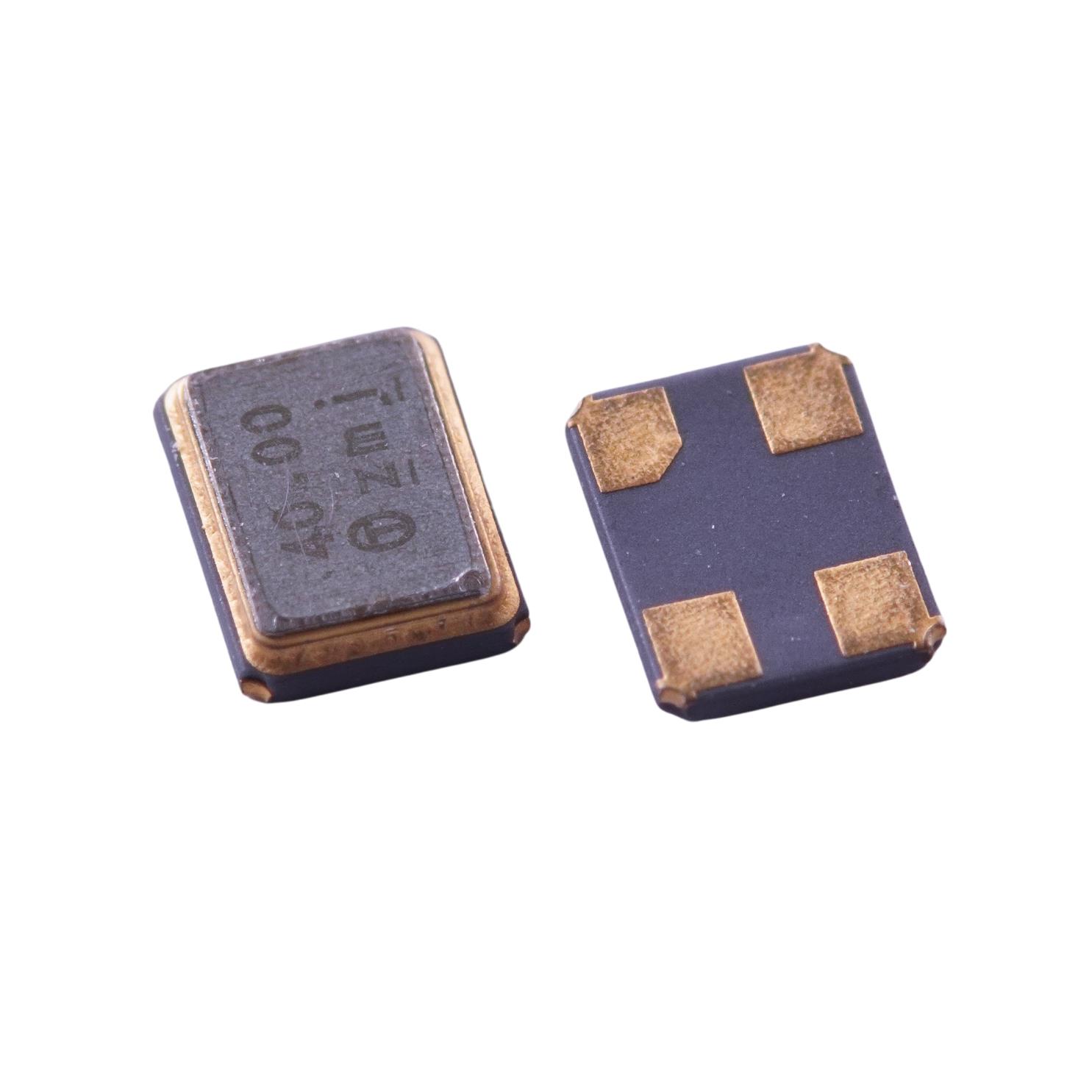

TZ2993DAAI42

Product Categories

Crystals

Manufacturer

Tai-Saw Technology TST

Describe

48/8/11/2.0X1.6

Encapsulation

-

Package

Tape & Reel (TR)

ROHS status

Yes

Price

USD $0.8500

Quantity