What are the components and modules of aluminum capacitors?

What are the Components and Modules of Aluminum Capacitors?

I. Introduction

Aluminum capacitors are a vital component in the world of electronics, playing a crucial role in various applications ranging from consumer devices to industrial machinery. These capacitors are known for their high capacitance values and cost-effectiveness, making them a popular choice among engineers and designers. In this article, we will explore the components and modules of aluminum capacitors, shedding light on their structure, manufacturing processes, applications, and the advantages and disadvantages they present.

II. Basic Principles of Capacitors

A. Definition of a Capacitor

A capacitor is an electronic component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy in the form of an electric charge.

B. How Capacitors Work

Capacitors work on the principle of electrostatics. When a voltage is applied, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. The amount of charge a capacitor can store is measured in farads (F), and the relationship between voltage, charge, and capacitance is described by the formula:

\[ Q = C \times V \]

where \( Q \) is the charge, \( C \) is the capacitance, and \( V \) is the voltage.

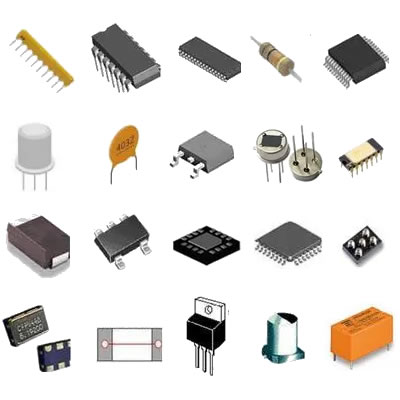

C. Types of Capacitors and Their Applications

There are several types of capacitors, including ceramic, film, tantalum, and aluminum capacitors. Each type has its unique characteristics and applications. Aluminum capacitors, in particular, are widely used in power supply circuits, audio equipment, and various electronic devices due to their high capacitance and reliability.

III. Structure of Aluminum Capacitors

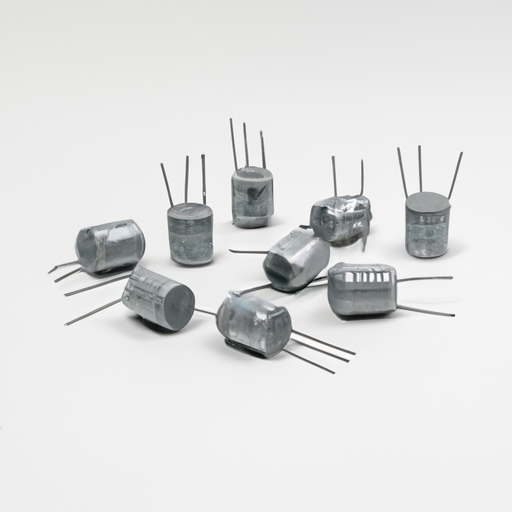

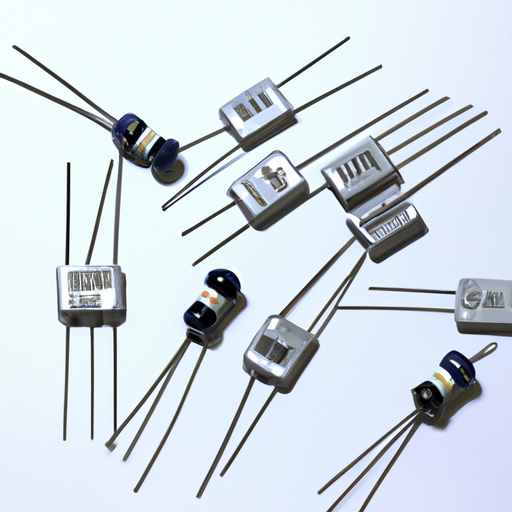

A. Overview of Aluminum Capacitor Design

Aluminum capacitors are electrolytic capacitors that utilize aluminum as the anode material. They are characterized by their cylindrical or rectangular shape and are often encased in a protective shell. The design of aluminum capacitors allows for a large surface area, which is essential for achieving high capacitance values.

B. Key Components

1. Anode

The anode is the positive terminal of the capacitor and is typically made of aluminum.

a. Material and Construction

The anode is constructed from a thin aluminum foil that is etched to increase its surface area. This etching process creates a rough surface, allowing for more charge storage.

b. Oxide Layer Formation

A crucial aspect of the anode is the formation of a thin oxide layer, which acts as the dielectric. This layer is formed through an electrochemical process, where the aluminum is oxidized in an electrolyte solution. The thickness of this oxide layer determines the voltage rating of the capacitor.

2. Cathode

The cathode is the negative terminal of the capacitor.

a. Material and Function

The cathode is usually made of a conductive material, such as aluminum or a conductive polymer. Its primary function is to provide a path for the current to flow back to the anode.

b. Role in the Capacitor

The cathode plays a vital role in the overall performance of the capacitor, as it helps maintain the balance of charge between the anode and cathode.

3. Electrolyte

The electrolyte is a crucial component of aluminum capacitors.

a. Types of Electrolytes Used

Aluminum capacitors typically use liquid electrolytes, which can be either aqueous or non-aqueous. Common electrolytes include ammonium borate and other organic solvents.

b. Importance of the Electrolyte

The electrolyte facilitates the movement of ions between the anode and cathode, allowing the capacitor to store and release energy efficiently.

4. Separator

The separator is a non-conductive material that prevents short circuits within the capacitor.

a. Function and Material

The separator is usually made of paper or plastic and is placed between the anode and cathode. Its primary function is to keep the two electrodes apart while allowing ionic movement through the electrolyte.

b. Importance in Preventing Short Circuits

The separator is critical in preventing short circuits, which can lead to capacitor failure and potentially hazardous situations.

IV. Modules of Aluminum Capacitors

A. Capacitor Case

The case of an aluminum capacitor provides physical protection and insulation.

1. Types of Cases (e.g., cylindrical, rectangular)

Aluminum capacitors come in various shapes, with cylindrical and rectangular cases being the most common. The choice of case type often depends on the application and space constraints.

2. Material Considerations

The casing is typically made of aluminum or other metals, which provide durability and protection against environmental factors.

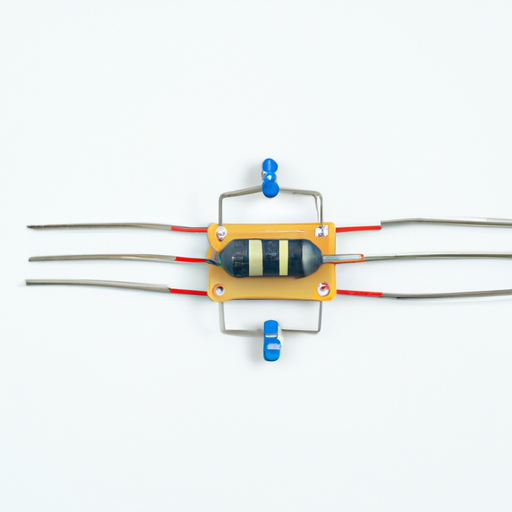

B. Terminals

Terminals are essential for connecting the capacitor to the circuit.

1. Types of Terminals (e.g., leaded, surface mount)

Aluminum capacitors can have different terminal types, including leaded terminals for through-hole mounting and surface mount terminals for compact designs.

2. Connection to Circuitry

The terminals must be securely connected to the circuit to ensure proper functionality and reliability.

C. Insulation

Insulation is crucial for the safe operation of aluminum capacitors.

1. Importance of Insulation

Insulation prevents electrical leakage and protects the capacitor from external factors that could affect its performance.

2. Materials Used for Insulation

Common insulation materials include plastic films and rubber, which provide effective barriers against moisture and contaminants.

V. Manufacturing Process of Aluminum Capacitors

A. Overview of the Manufacturing Steps

The manufacturing process of aluminum capacitors involves several steps, including the preparation of the anode and cathode, oxide layer formation, electrolyte filling, and assembly of the capacitor case.

B. Quality Control Measures

Quality control is essential in the manufacturing process to ensure that the capacitors meet industry standards and specifications. This includes testing for capacitance, leakage current, and voltage ratings.

C. Innovations in Manufacturing Techniques

Recent advancements in manufacturing techniques have led to improved efficiency and performance of aluminum capacitors. Innovations such as automated assembly lines and advanced testing methods have enhanced the reliability of these components.

VI. Applications of Aluminum Capacitors

A. Consumer Electronics

Aluminum capacitors are widely used in consumer electronics, including smartphones, televisions, and audio equipment, where they help stabilize voltage and filter signals.

B. Industrial Applications

In industrial settings, aluminum capacitors are used in power supply systems, motor drives, and control circuits, providing essential energy storage and filtering capabilities.

C. Automotive Industry

The automotive industry relies on aluminum capacitors for various applications, including engine control units, infotainment systems, and electric vehicle power management.

D. Renewable Energy Systems

Aluminum capacitors play a significant role in renewable energy systems, such as solar inverters and wind turbine controllers, where they help manage energy storage and conversion.

VII. Advantages and Disadvantages of Aluminum Capacitors

A. Advantages

1. Cost-Effectiveness

Aluminum capacitors are relatively inexpensive compared to other capacitor types, making them an attractive option for manufacturers.

2. High Capacitance Values

They offer high capacitance values in a compact size, allowing for efficient energy storage in various applications.

3. Lightweight and Compact Design

The lightweight nature of aluminum capacitors makes them suitable for portable devices and applications where space is limited.

B. Disadvantages

1. Limited Lifespan

One of the main drawbacks of aluminum capacitors is their limited lifespan, which can be affected by factors such as temperature and voltage stress.

2. Temperature Sensitivity

Aluminum capacitors are sensitive to temperature variations, which can impact their performance and reliability.

3. Leakage Current Issues

Leakage current can be a concern with aluminum capacitors, leading to energy loss and potential failure in critical applications.

VIII. Conclusion

In summary, aluminum capacitors are essential components in modern electronics, characterized by their unique structure and functionality. Understanding the components and modules of these capacitors is crucial for engineers and designers as they navigate the complexities of electronic design. As technology continues to evolve, advancements in aluminum capacitor technology will likely lead to improved performance and new applications, solidifying their importance in the electronics industry.

IX. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Applied Physics

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Online Resources and Databases

- Digi-Key Electronics

- Mouser Electronics

This comprehensive overview of aluminum capacitors highlights their significance in various applications and the intricate details of their components and modules. Understanding these elements is essential for anyone involved in electronics design and manufacturing.